- Home

- Soundproofing Company Products

- Additional Soundproofing Products

- Automatic Door Bottom

- Automatic Door Bottom

Automatic Door Bottom

Call for Best Price

800-397-8791

ZERO designs and builds automatic door bottoms to last. Our automatic door bottoms have been tested through 5 million cycles.

Automatic Door Bottom

-

Description

Secured directly to the door jamb, these acoustical gaskets feature our unique Compress-O-Matic™ design with a sound-absorbing neoprene bulb that compresses to form a tight seal as the door is closed.

Both models include adjusting screws for field correction of irregular clearances that might compromise actual sound performance.

When used with a metal cased-opening frame, the #770 offers the added benefit of eliminating the need for an additional frame stop–and its unaesthetic projection into the door opening.

The gasket is also listed for use with both wood and metal acoustical doors with fire listings ranging from 20 to 90 minutes under both negative a positive-pressure testing standards. It is exceptional engineering, design features, and performance have made the #770 our long-time favorite for acoustical engineers and specifier.

Features

- UL Rated

- Aluminum Finish

- Solid neoprene seal - weatherproof and remains flexible in extreme temperatures.

- Fully Adjustable up to .3 inches

- Installed as surface-mounted

- Easily Trimmable

-

Technical Specifications

- Width: 7/8"

- Depth: 1 1/2"

- Size: Standard 3' 0" x 6' 8" Door Opening

- Finish: Brushed Aluminum

- Gasket: Premium Sponge Neoprene

Positive Pressure Tested Gasket Material for Fire Doors. Intended for application to/with listed steel-covered composite; hollow metal-type fire doors rated up to 3 hours; wood- and plastic-covered composite-type fire doors rated up to 1 1/2 hours; wood-core type fire floors rated up to 20 minutes.

Also classified in accordance with UBC 7-2, Fire Tests of Door Assemblies (1997).

Meets UL10B, UL10C and UBC 7-2 (1997) part 2 Category H. Can use on 'S' Labeled doors. 17L5

-

Installation

The experts at Soundproofing Company have created detailed step-by-step instruction manuals that are included with every purchase.

Download Datasheet -

Shipping & Liability Statement

$100 Minimum Order for FREE SHIPPING

Additional $25 Shipping Charge for orders less than $100.

Warehouse Fee of +$10 per order.RETURN POLICY:

60 Days on all Returns All returned unused items are subject to warehouse and 20% re-stock fees. No Returns on Open/Partial Cases, Pails, Single Tubes, Outlet Putty PadsThe Soundproofing Company presents these products and construction concepts with the understanding that local Building Codes vary. It is the responsibility of the installer to ensure product is properly installed, and that these concepts meet local Building Code. The Soundproofing Company is not liable for mis-installation or non-compliance with local code.

GROUND SHIPPING:

WAREHOUSE ADDRESS:

Soundproofing Company, Inc.

527 W. Morley Dr. Saginaw, MI. 48601

Support: (800) 397-8791

www.soundproofingcompany.com

Soundproofing Solutions

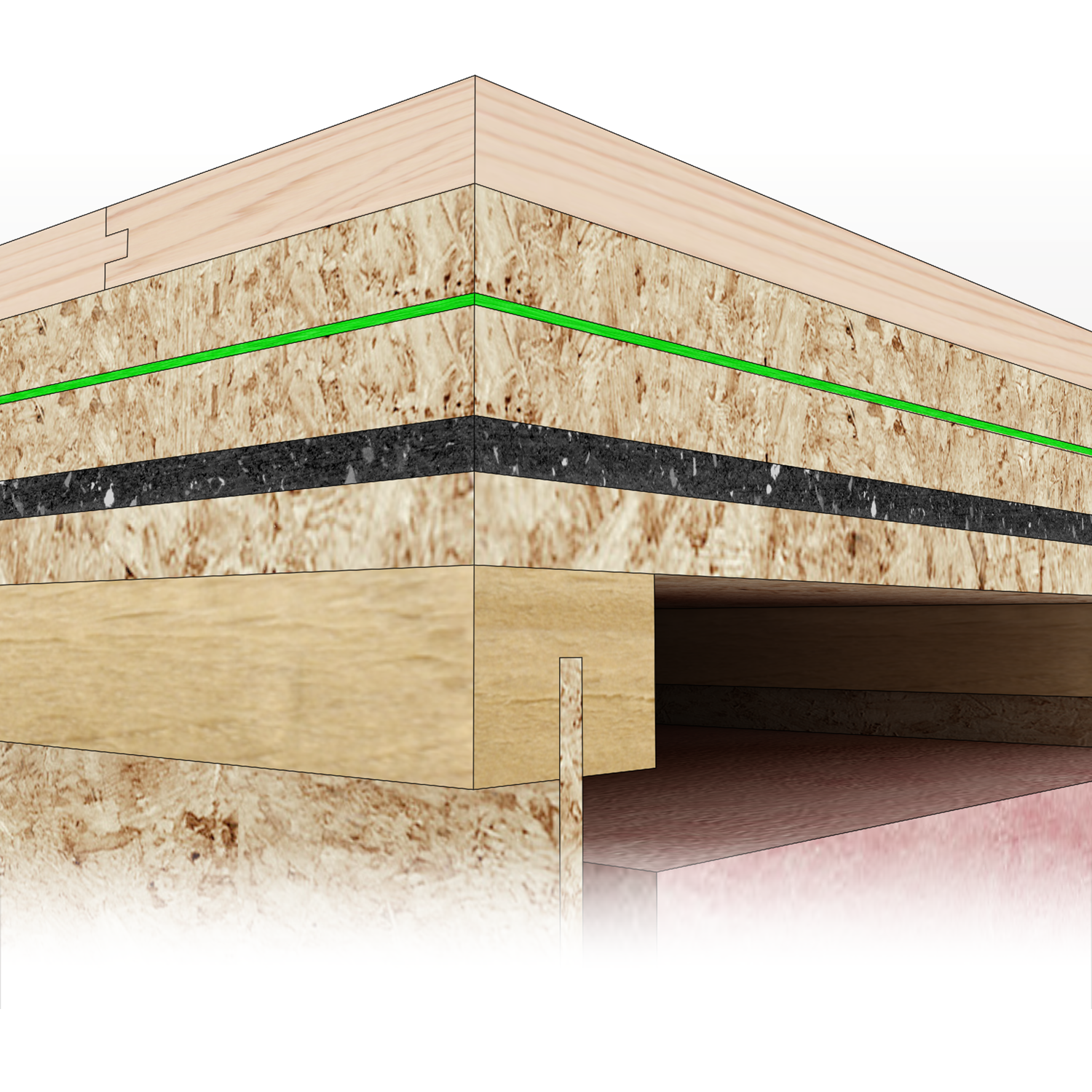

Soundproofing Floors

Noisy floors are a significant and growing issue as more people are opting for hard surface flooring. This creates distinct soundproofing challenges. We offer solutions tailored to your commercial or residential needs.

Soundproofing Ceilings

Impact noise coming through a ceiling is one of the worst soundproofing problems. A footfall imparts a violent level of energy into the ceiling. We offer ceiling solutions to quiet even the most problematic footfall noise.

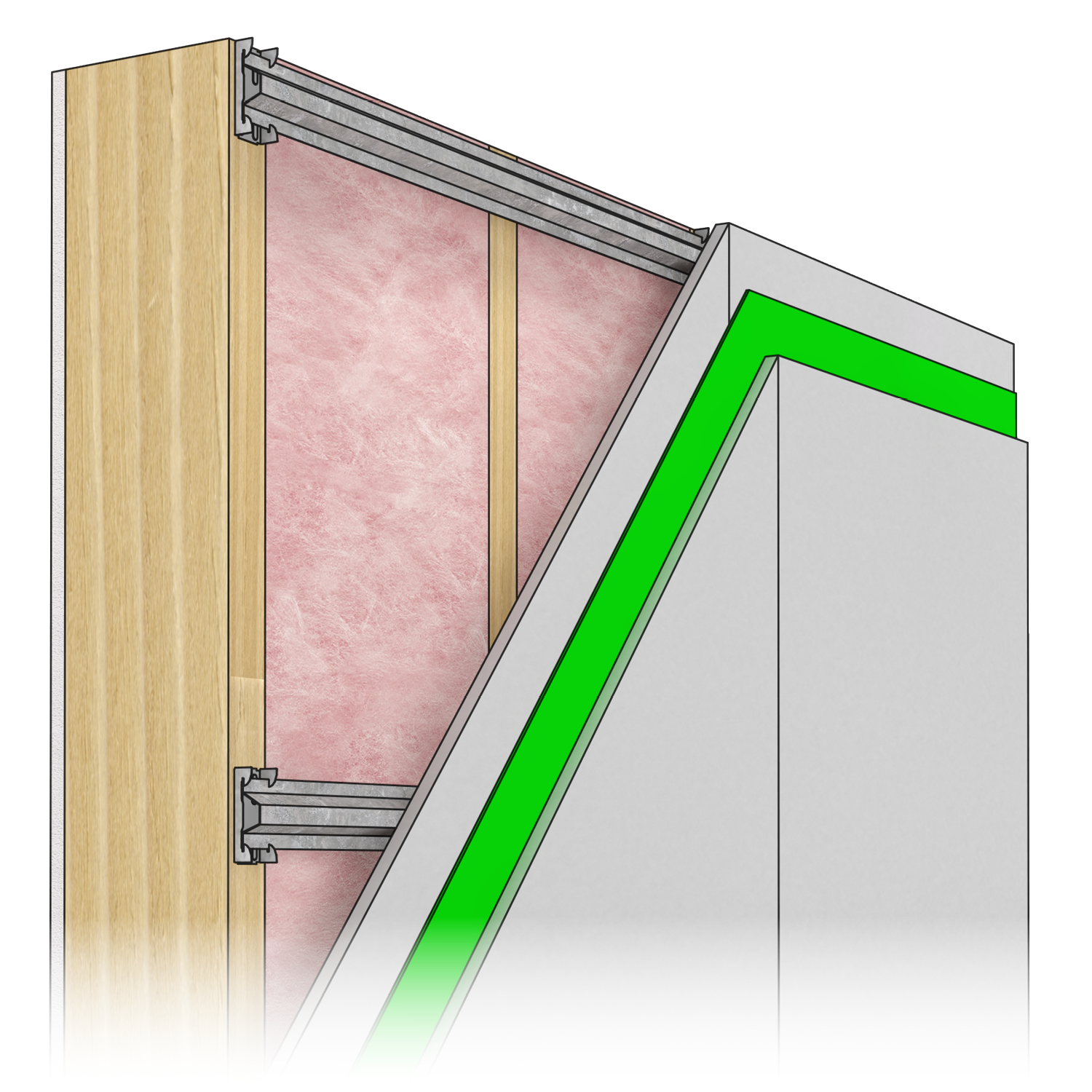

Soundproofing Walls

Shared interior walls don't offer much in the way of sound isolation. There are good approaches and bad, and you only want to do this once. Our lab-certified wall solutions will help ensure you get it right the first time.

Related Products

Recently Viewed