Pipes, Plumbing, and Ductwork

We spend a lot of time working on the basic walls, ceilings, and floors when designing a room. These are the large surfaces, after all. There are many ways to compromise the system, and the holes from pipes and ducts are a big area to account for.

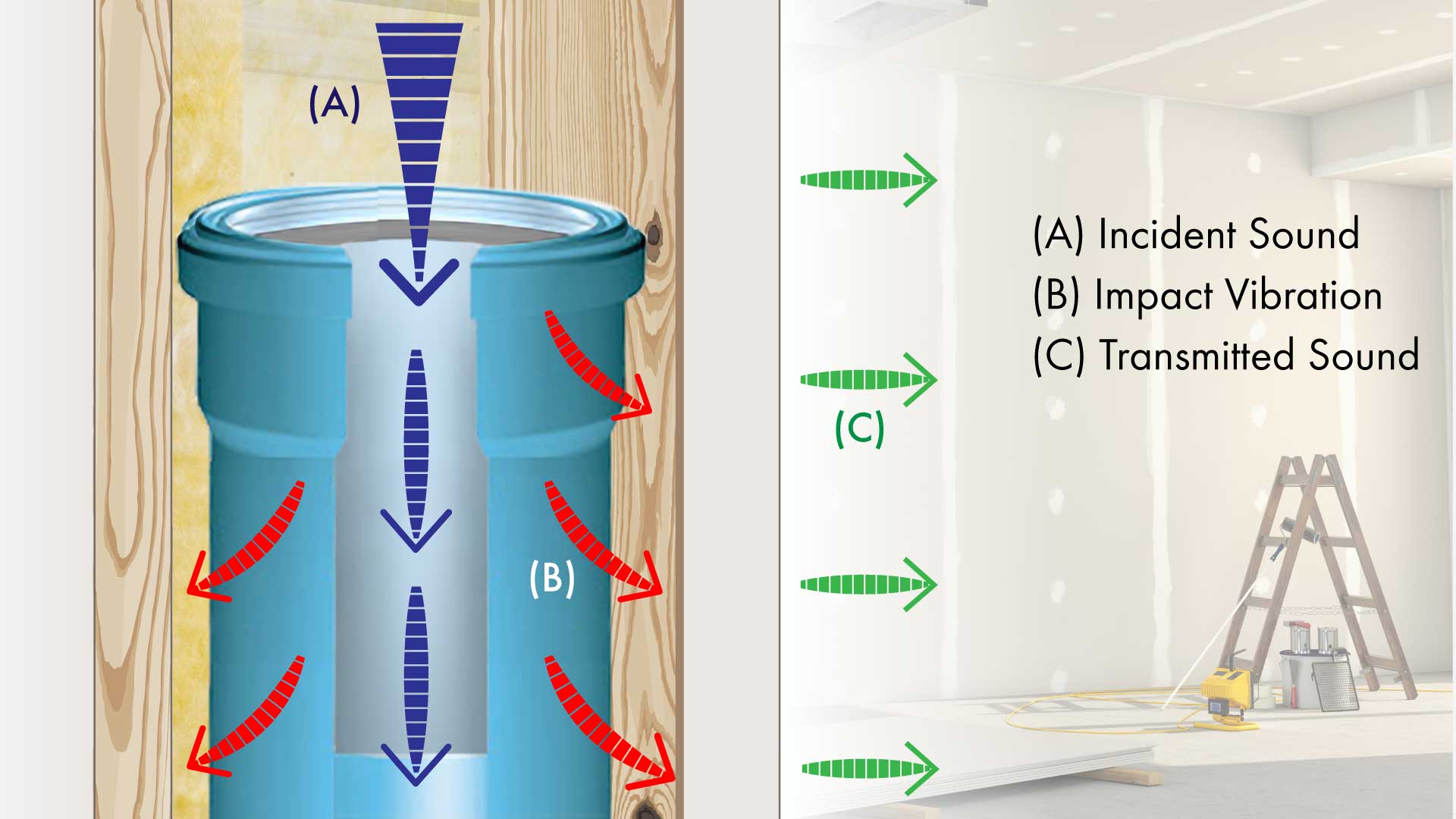

Pipes and ducts (as well as water and gas lines to a degree) introduce a pathway for sound vibration to enter and leave the sound-isolated area. Sound vibration can travel within the center of the pipe or duct, just like water and air does. Vibration can also conduct within the walls of the pipe or duct. You might feel the pipe vibrate.

Let’s separately look at the two main systems of concern - waste pipes and air ducts.

Waste pipes carry a lot of water all at once, as with a shower running or a toilet flushing. This can cause a slow water noise to enter the framing, as well as a crashing water sound as the pipe changes direction. Sometimes that’s in your dining room ceiling… No fun when guests are over.

It should be noted that it’s technically more beneficial to have a massive cast iron waste pipe, rather than the much lighter PVC. More massive things tend to conduct less sound, but there’s an additional cost associated with the cast iron. One might also consider simply wrapping the PVC pipe with one of a number of pipe wraps or Mass Loaded Vinyl, and indeed the Soundproofing Company used to sell a specific pipe wrap 10 years ago for this expressed purpose. We determined, however, that various pipe wraps were unnecessary, and instead a builder should rely more on the technique used to install the pipe.

Firstly, let’s understand that the vibrating pipe will introduce that vibration into the building framing. The pipe conducts this vibration, and now so is the framing. When the framing conducts this vibration to something like a sheet of drywall, the drywall now acts like a giant speaker, faithfully reproducing the noise. We want to avoid/minimize the contact between the pipe and the framing.

Make sure the wall or ceiling cavity leaves enough room all the way around the pipe. Oversize the holes in the top and bottom wall plates. Center the pipe in the hole and seal with a fire-rated foam or sealant. You might need a little spacer to keep the pipe centered while the foam/sealant dries. The pipe contact with the less conductive foam is much less of a problem than the pipe contacting the highly conductive framing.

When securing the pipe within the wall or ceiling joist cavity, take a bit of the insulation you’re using and wad it up into a little puck, and place that between the pipe and the framing. Use as few pucks as you can. When using a strap to hold the pipe to the stud or joist, don’t unnecessarily tighten this system down. More pressure and more contact area means more unwanted conduction.

Let’s not let the drywall or subfloor touch the pipe. Again, have enough space available for this. After proper pipe installation, you can insulate the cavity very loosely. You may have to trim the insulation so it’s not jammed up against the pipe. Compressed insulation will conduct a vibration.

You may choose to treat the drywall in some fashion as well. This might be simply the use of 5/8” drywall instead of the 1/2” lightweight drywall used ubiquitously today. You might double up on the same drywall, or introduce decoupling with Clips & Channels.

Air Ducts also require attention, as they are conductors of sound and vibration. Forced air systems use ductwork, which unfortunately amounts to big holes in the walls and ceiling, with pipes conducting sound all over the place. Ductwork is not our friend, acoustically.

One issue with the duct isn’t the duct itself. It’s the big hole in the drywall for the vent. The sound energy is like a bullet. If you fired a bullet at the vent, the bullet won’t make a right-angle turn and follow the duct. The bullet would rip through the duct material and lodge itself in the framing. This is what a sound wave will do. You can see that twists and turns and S-shape bends don’t affect the bullet lodging itself in the framing.

So what can you do with ducts? You could choose to:

Not have any ducts and look at a dedicated Mini-Split.

Build mufflers for the supplies and return lines. We have articles on building these.

Use 1” Linear Slot Diffusors instead of rectangular grill diffusors.

Simply live with the leaks associated with ducts.