Soundproofing Walls

The Soundproofing Company offers high-quality solutions to achieve maximum sound dampening, sound isolation, and overall noise reduction. Our solutions for soundproofing walls are ideal for commercial, condo, apartment, and residential walls, home theater rooms, or any other space where noise travels through walls.

Check out our case studies to see how we've helped customers just like you solve their stickiest soundproofing problems.

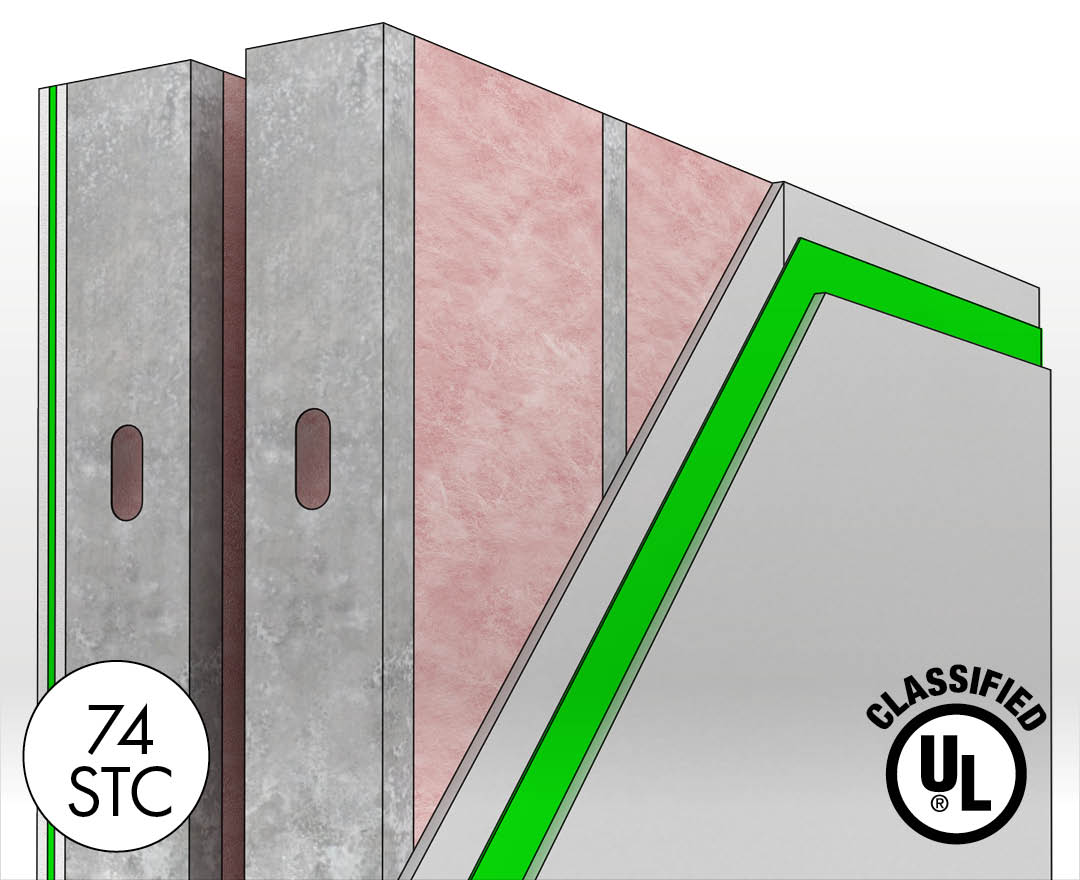

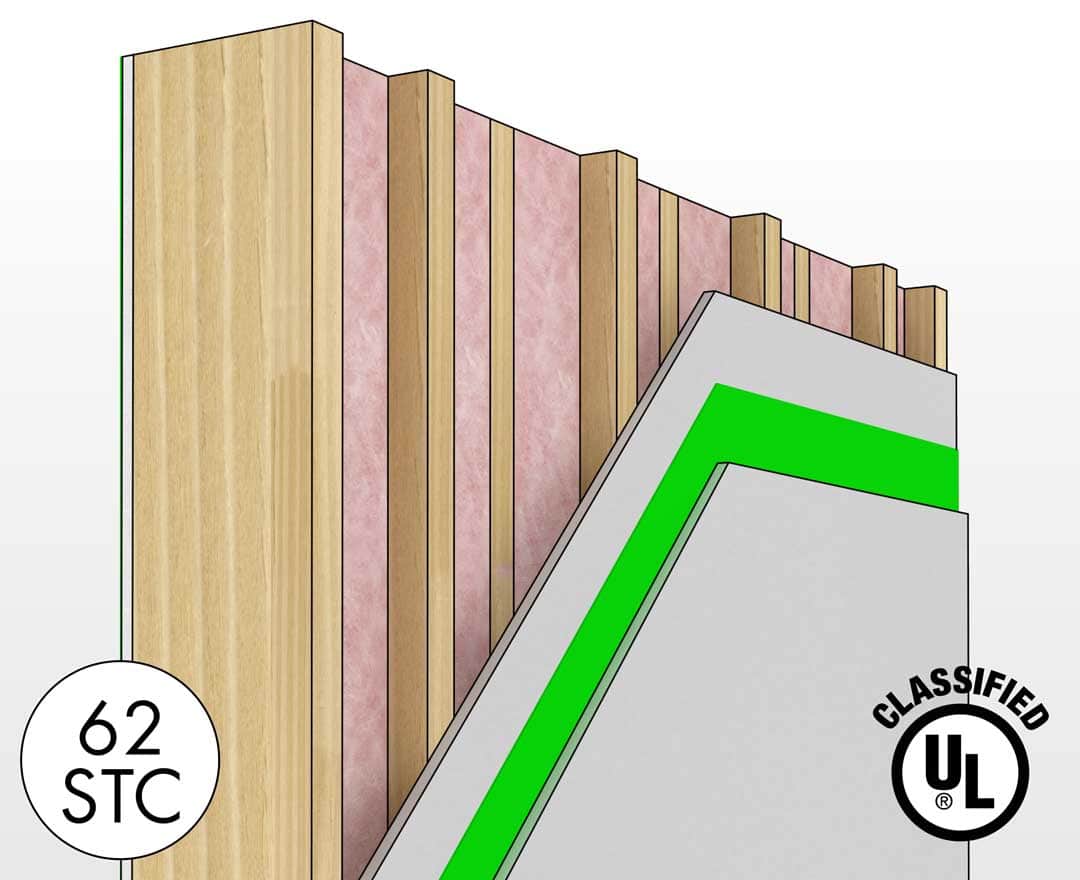

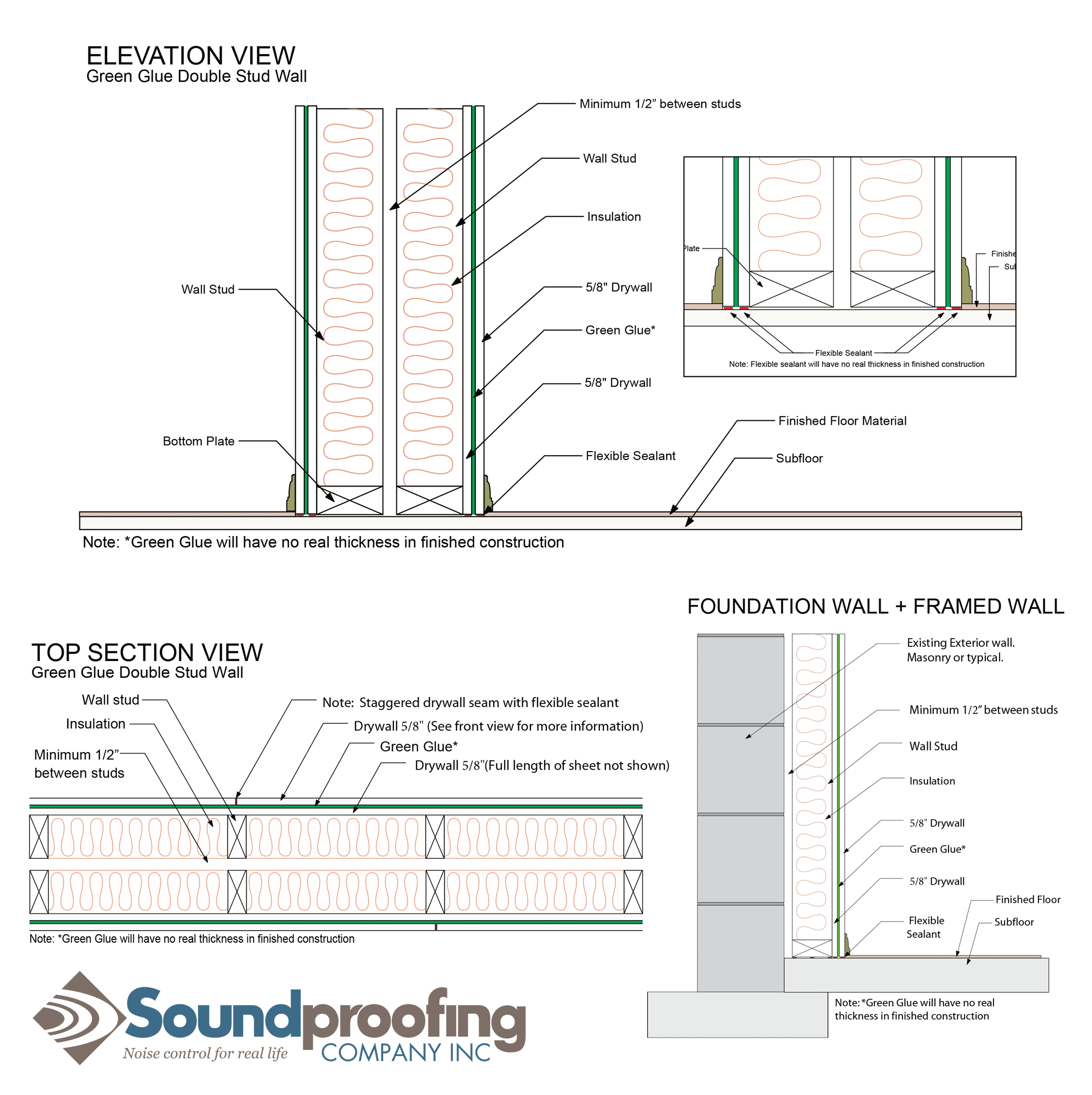

The Double Stud Wall with Green Glue is our highest performing wall assembly. Currently, most acoustical labs have a hard time plotting double-wall performance accurately, as the wall often exceeds the flanking limits of the lab.

- "Level 3" - Commercial quality sound isolation

- Double stud wall assembly

- Highest performance decoupled isolation

- Best for heavy loads

- Best for low-frequency bass

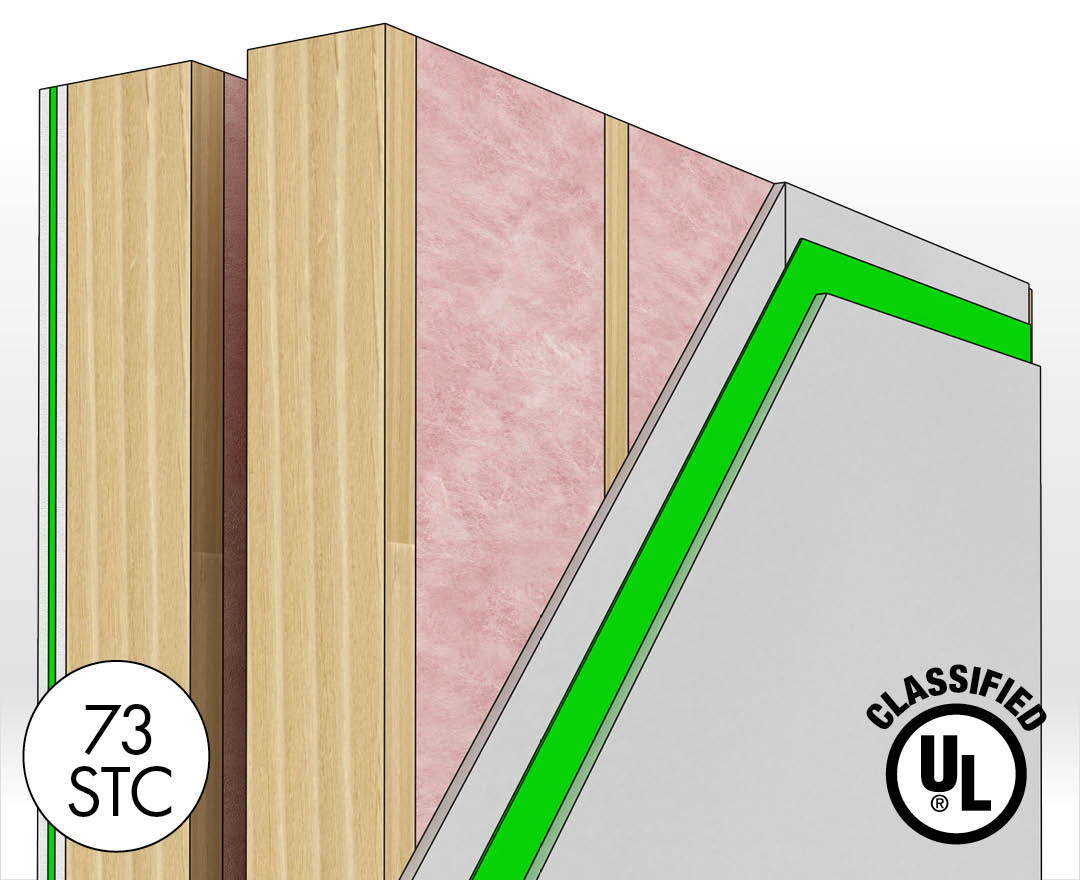

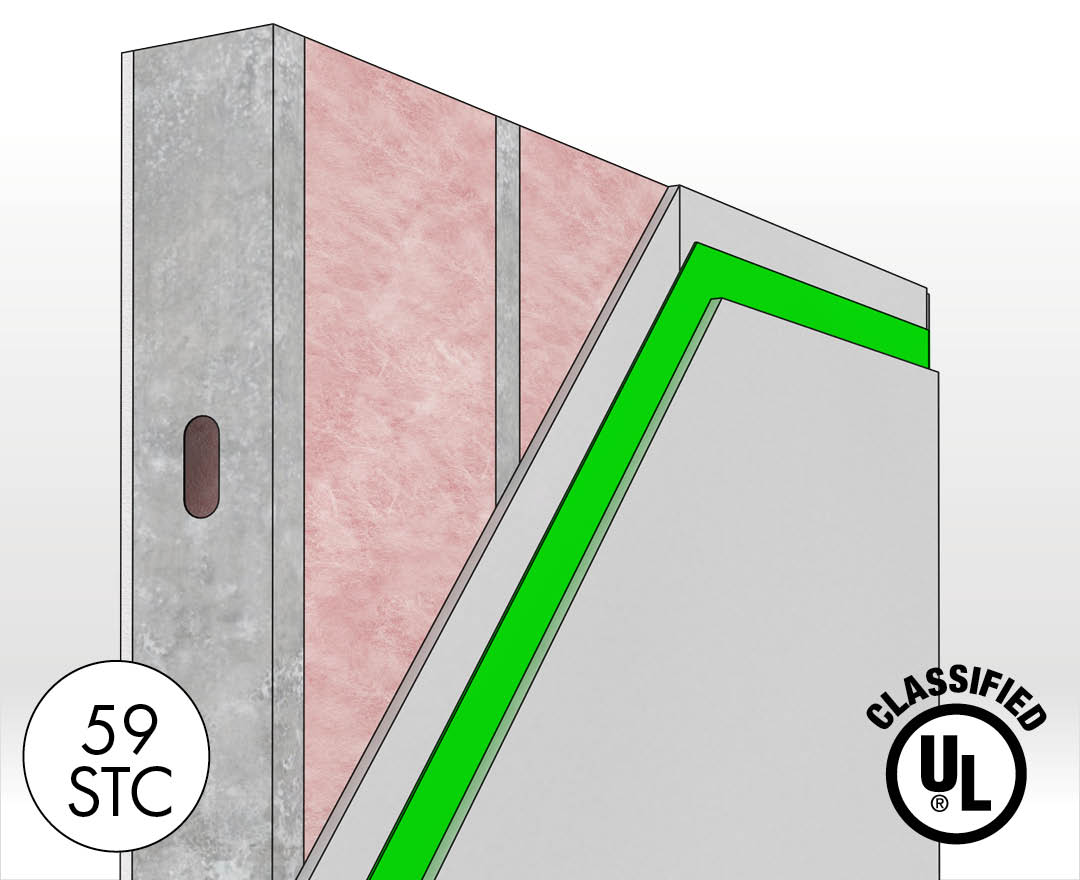

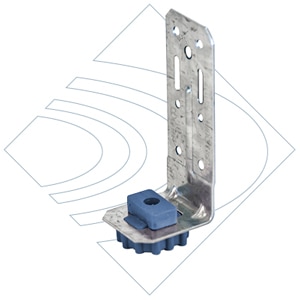

When space won’t allow a double stud wall, soundproofing clips and channels become the choice. While not able to accommodate heavy loads such as kitchen cabinets, you can certainly install pictures and small shelves.

- "Level 2" - Light-duty residential noise reduction

- IB-1 soundproofing clip & channel wall

- High performance decoupled isolation

- Lowest profile, higher performance solutions

- Not for heavy loads (cabinets, TVs, etc.)

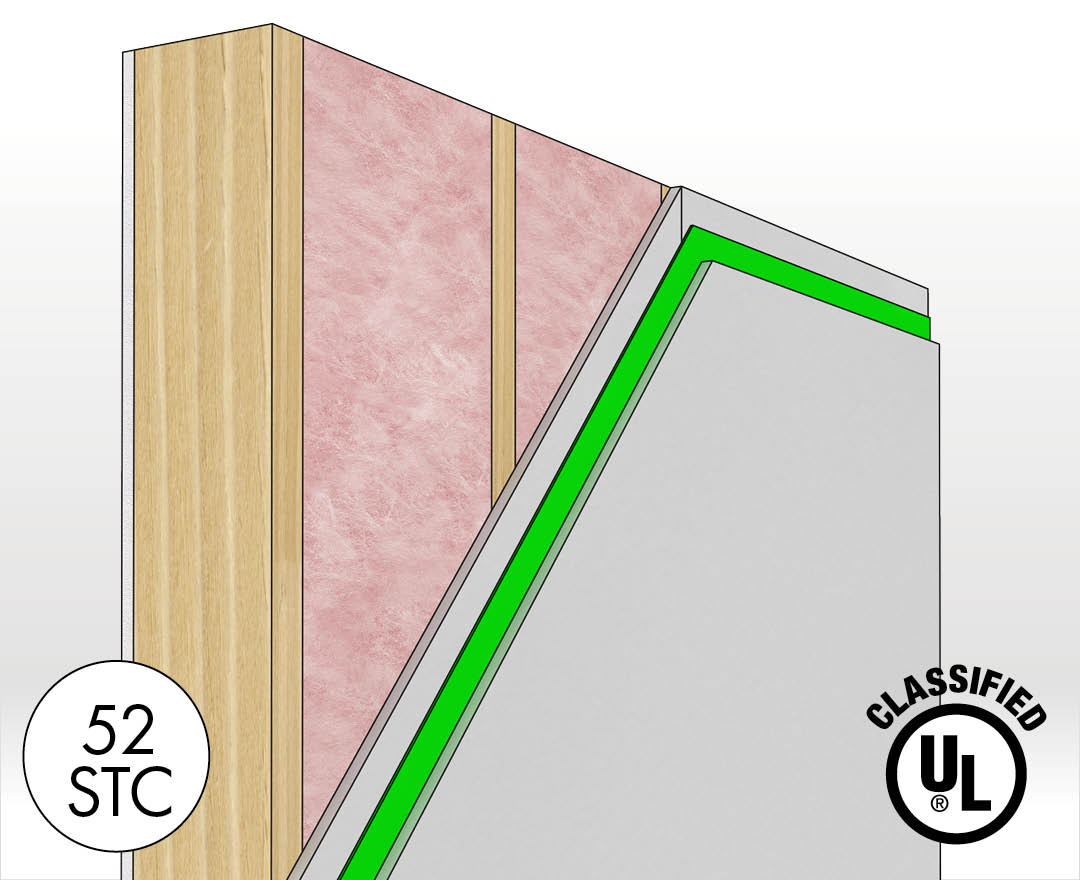

Adding Green Glue and drywall directly to the existing drywall is common; however not as high performance as a decoupled Soundproof Clip Wall. Install on walls that have 24" O.C. framing. Green Glue is recommended over MLV, Resilient Channel, Soundboard, etc.

- "Level 1" - When cost is the primary consideration

- Single stud wall with Green Glue

- Less isolation, drywall shares one stud (coupled)

- Not recommended for 16" OC framing

Additional Wall Assemblies

Staggered Stud Walls

Acoustical Reference Only. We do not suggest installing Staggered stud walls due to the shared top and bottom plate. This causes problems in acoustic performance.

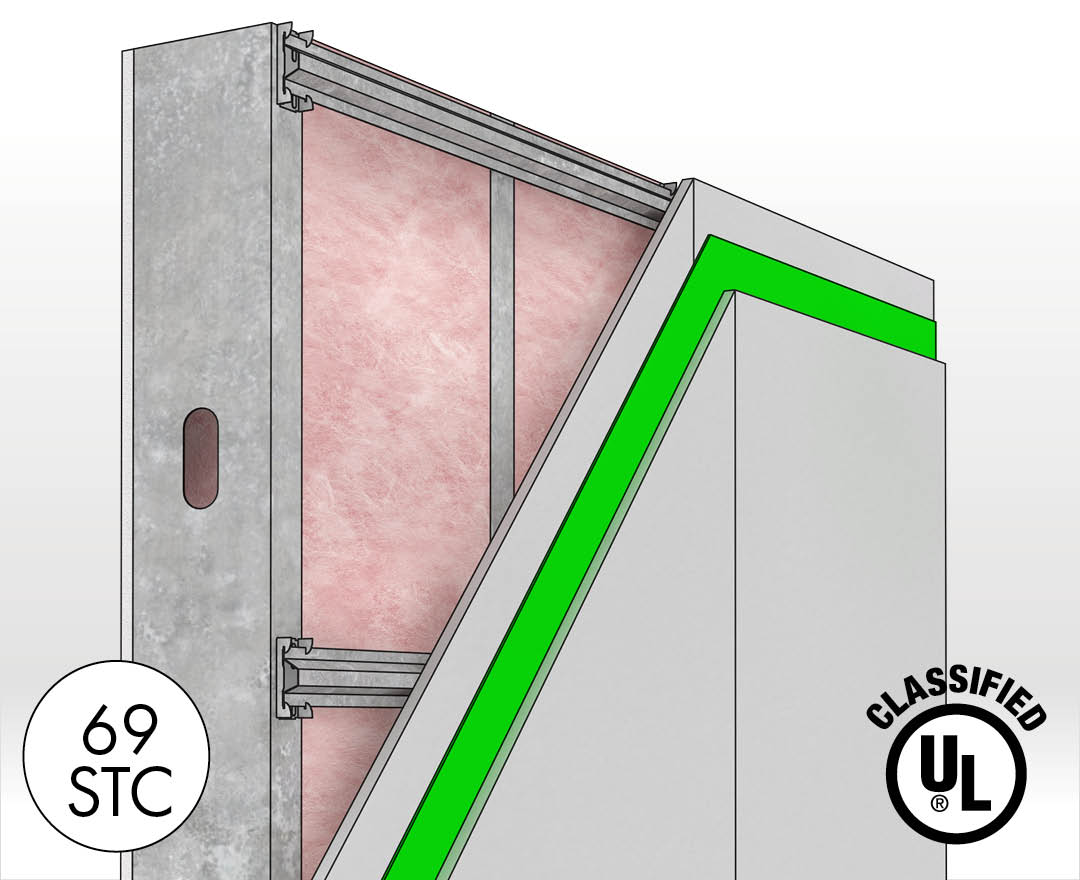

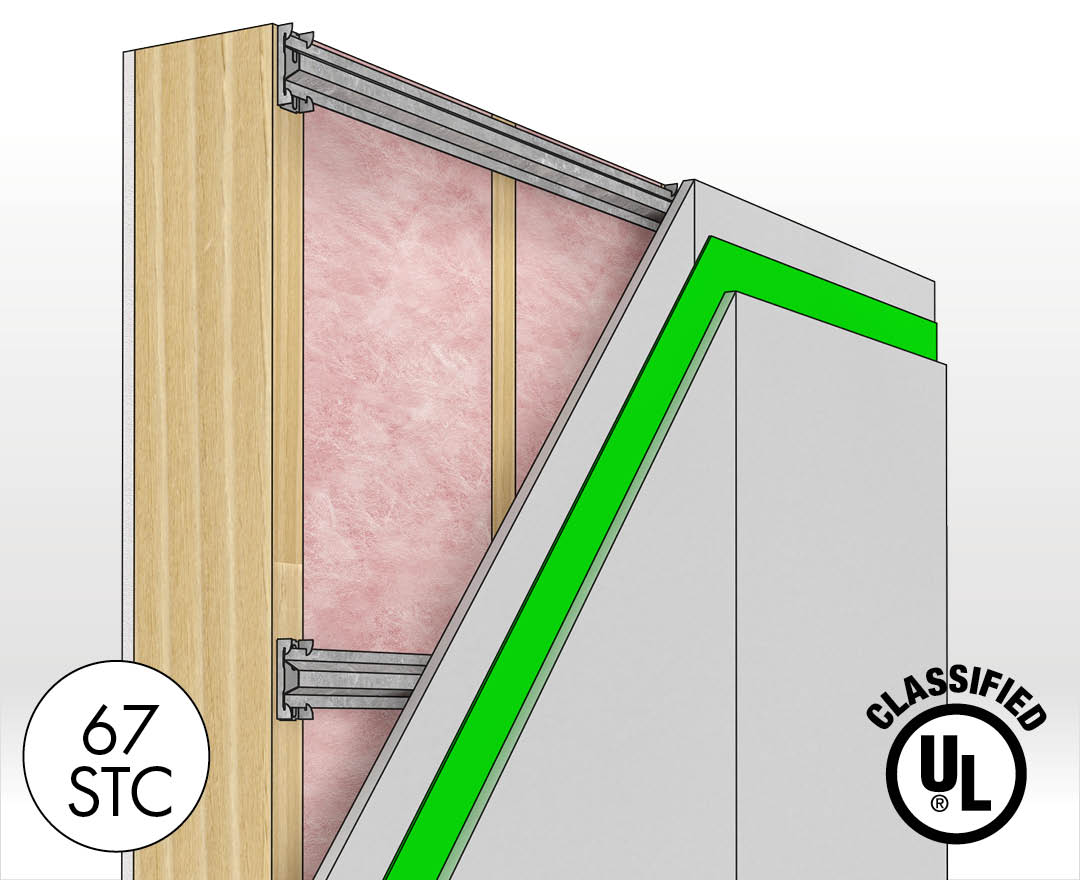

Soundproof IB-1 Clip Walls

Clips perform two main functions. First, because they are spaced in rows 24″ apart (generally), the drywall is attached with far fewer contact areas. Second, clips and hat tracks are resilient. They allow a wall to flex, and this increases sound isolation while lowering the troublesome primary low-frequency resonance point.

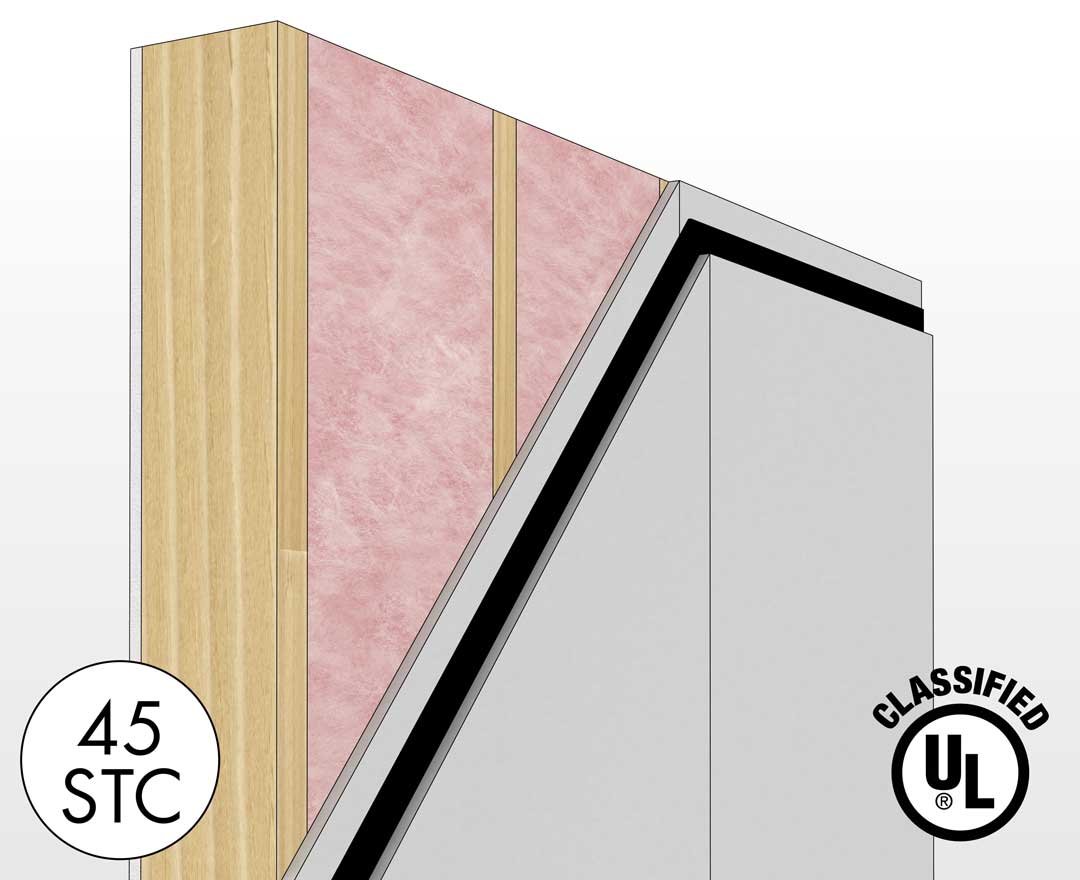

Resilient Channel Walls

Acoustical Reference Only: We do not suggest installing Resilient Channel walls. They test well in the lab but when installed in the field they are seriously prone to malfunction.

Mass Loaded Vinyl Walls

Mass Loaded Vinyl (MLV) is a classic sound transmission blocker but limited in real-life performance. Due to MLV’s flexibility, it is ideal for use with ducts, pipes, and steel framing.

Gypsum Wall Assemblies

Standard 5/8” Type X gypsum wall assembly. Great mass at 70+ pounds a board and cheap at $12 a sheet, but a single layer it does not do much to stop sound.

Get started today.

The Soundproofing Company wants to make sure your job is done right the first time; that's why it's important that we talk before you choose your products. These consultations are part of our service and are offered at no cost to you.

We have the lab reports, materials, diagrams, SIMS (Soundproofing Installation Manuals), and experience you need.

SINCE 1999 - The Soundproofing Company has over two decades of experience with soundproofing.

FREE CONSULTATION - Buy products with confidence. We know what works and the myths you should avoid.

CALL ANY TIME - Full phone support throughout the construction phase of your soundproofing project.

FULLY ILLUSTRATED MANUALS with material purchase (SIM). Detailed guides to give to your contractor.

CUSTOM FREIGHT QUOTES - Our shipping department knows how to get your order shipped to you quickly at the best price.